- Product Description

- Design Parameters

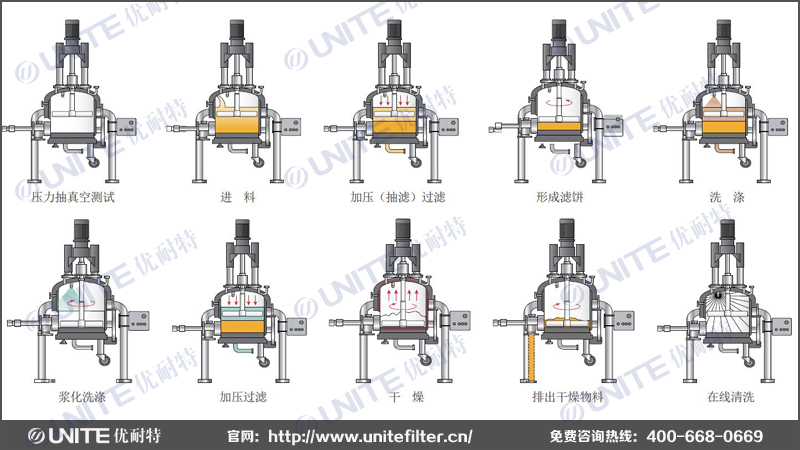

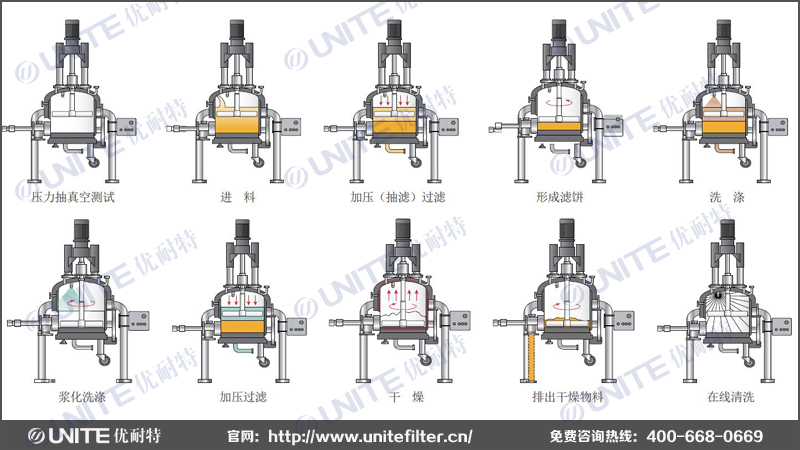

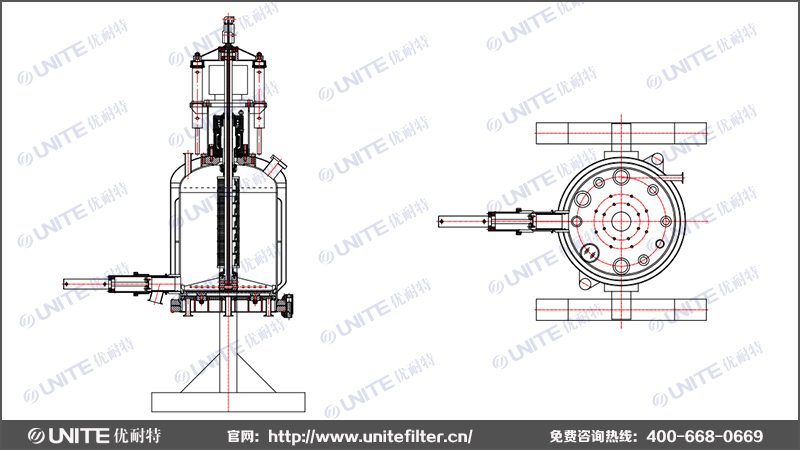

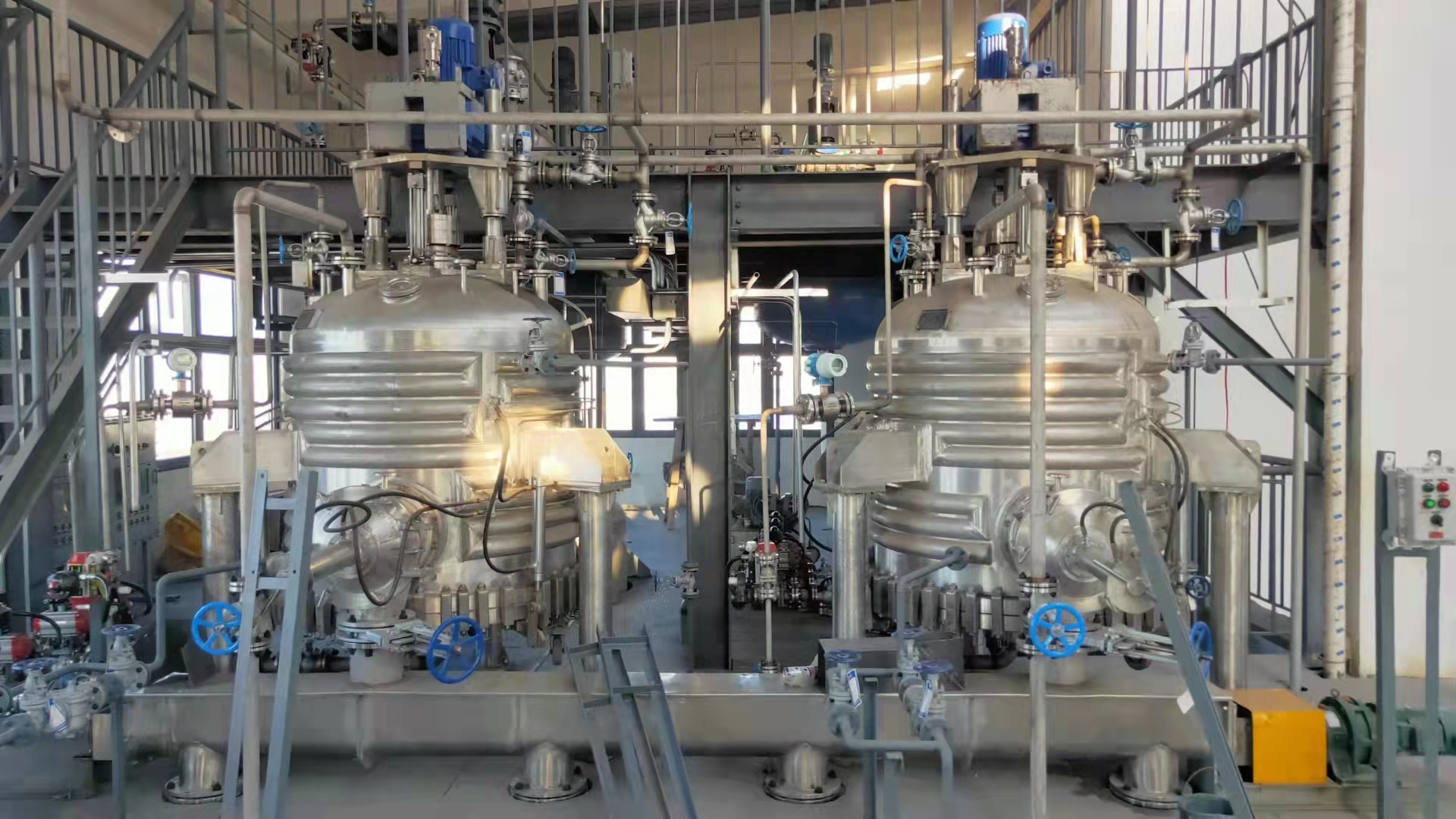

The unique three in one filter washing dryer is a new generation of solid Liquid separation process equipment. The material can be filtered, washed and dried in a closed container The utilization rate of the equipment has been greatly improved. To avoid the pollution of the environment Environmental pollution of materials, reduction of material transport loss, saving solvent consumption, suitable for batch batch Quantity production. The union system is divided into two series: aseptic and industrial. U-mfcd series sterile multi-functional filter washing dryer is mainly used for the production of sterile raw materials Yes, the polishing level of all parts inside the filter reaches 0.4 RA, which fully meets the FDA production requirements. U-mfpf series industrial multi-functional filter washing dryer is a kind of collection filtration, washing, drying A multi-functional solid-liquid separation equipment with mixing and automatic slag removal. Solution: Users are very strict with the process requirements of filtration, washing and drying. No matter the surrounding environment or temperature has a great impact on the corrosion of equipment materials, but the efficiency of each production stage must be guaranteed And the quality of the product. These conditions drive the product to use high-quality steel or nickel base alloy to meet the requirements. This flexible configuration ensures that each product can meet different application areas and production requirements of customers Product characteristics and process requirements.

Liquid separation process equipment. The material can be filtered, washed and dried in a closed container The utilization rate of the equipment has been greatly improved. To avoid the pollution of the environment Environmental pollution of materials, reduction of material transport loss, saving solvent consumption, suitable for batch batch Quantity production. The union system is divided into two series: aseptic and industrial. U-mfcd series sterile multi-functional filter washing dryer is mainly used for the production of sterile raw materials Yes, the polishing level of all parts inside the filter reaches 0.4 RA, which fully meets the FDA production requirements. U-mfpf series industrial multi-functional filter washing dryer is a kind of collection filtration, washing, drying A multi-functional solid-liquid separation equipment with mixing and automatic slag removal. Solution: Users are very strict with the process requirements of filtration, washing and drying. No matter the surrounding environment or temperature has a great impact on the corrosion of equipment materials, but the efficiency of each production stage must be guaranteed And the quality of the product. These conditions drive the product to use high-quality steel or nickel base alloy to meet the requirements. This flexible configuration ensures that each product can meet different application areas and production requirements of customers Product characteristics and process requirements.

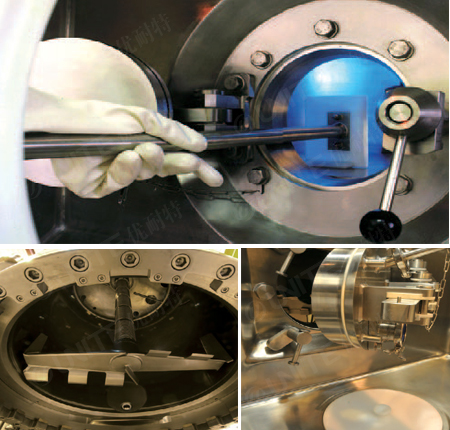

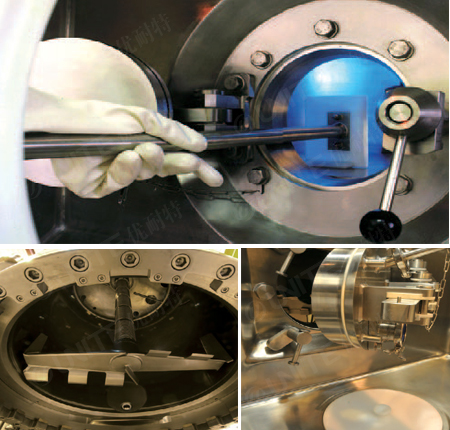

以在同一容器内 Continuous operation in the whole process of filtration, washing and drying; Operate under pressure or vacuum to realize solid-liquid separation. The cake is evenly distributed and the solid-liquid separation effect is good; The hydraulic pressure controls the rise and fall of the mixing system, and maximizes the slag holding space in the filtration; The mixing paddle is lifted and stirred, so that the filter cake and cleaning solution are fully mixed during cleaning, and the filter cake is fully washed; The drying time is greatly reduced and the efficiency is improved; The liquid outlet valve is controlled by many kinds, and the solid discharge system automatically discharges the material, reducing the labor intensity; It can be cleaned and sterilized online; The whole operation can be carried out under N2 protection, safe and reliable; Fully comply with GMP and FDA production requirements; The filter base plate is detachable, which is helpful for the thorough cleaning of the equipment and is suitable for the production of sterile APIs.

以在同一容器内 Continuous operation in the whole process of filtration, washing and drying; Operate under pressure or vacuum to realize solid-liquid separation. The cake is evenly distributed and the solid-liquid separation effect is good; The hydraulic pressure controls the rise and fall of the mixing system, and maximizes the slag holding space in the filtration; The mixing paddle is lifted and stirred, so that the filter cake and cleaning solution are fully mixed during cleaning, and the filter cake is fully washed; The drying time is greatly reduced and the efficiency is improved; The liquid outlet valve is controlled by many kinds, and the solid discharge system automatically discharges the material, reducing the labor intensity; It can be cleaned and sterilized online; The whole operation can be carried out under N2 protection, safe and reliable; Fully comply with GMP and FDA production requirements; The filter base plate is detachable, which is helpful for the thorough cleaning of the equipment and is suitable for the production of sterile APIs.

Liquid separation process equipment. The material can be filtered, washed and dried in a closed container The utilization rate of the equipment has been greatly improved. To avoid the pollution of the environment Environmental pollution of materials, reduction of material transport loss, saving solvent consumption, suitable for batch batch Quantity production. The union system is divided into two series: aseptic and industrial. U-mfcd series sterile multi-functional filter washing dryer is mainly used for the production of sterile raw materials Yes, the polishing level of all parts inside the filter reaches 0.4 RA, which fully meets the FDA production requirements. U-mfpf series industrial multi-functional filter washing dryer is a kind of collection filtration, washing, drying A multi-functional solid-liquid separation equipment with mixing and automatic slag removal. Solution: Users are very strict with the process requirements of filtration, washing and drying. No matter the surrounding environment or temperature has a great impact on the corrosion of equipment materials, but the efficiency of each production stage must be guaranteed And the quality of the product. These conditions drive the product to use high-quality steel or nickel base alloy to meet the requirements. This flexible configuration ensures that each product can meet different application areas and production requirements of customers Product characteristics and process requirements.

Liquid separation process equipment. The material can be filtered, washed and dried in a closed container The utilization rate of the equipment has been greatly improved. To avoid the pollution of the environment Environmental pollution of materials, reduction of material transport loss, saving solvent consumption, suitable for batch batch Quantity production. The union system is divided into two series: aseptic and industrial. U-mfcd series sterile multi-functional filter washing dryer is mainly used for the production of sterile raw materials Yes, the polishing level of all parts inside the filter reaches 0.4 RA, which fully meets the FDA production requirements. U-mfpf series industrial multi-functional filter washing dryer is a kind of collection filtration, washing, drying A multi-functional solid-liquid separation equipment with mixing and automatic slag removal. Solution: Users are very strict with the process requirements of filtration, washing and drying. No matter the surrounding environment or temperature has a great impact on the corrosion of equipment materials, but the efficiency of each production stage must be guaranteed And the quality of the product. These conditions drive the product to use high-quality steel or nickel base alloy to meet the requirements. This flexible configuration ensures that each product can meet different application areas and production requirements of customers Product characteristics and process requirements.

以在同一容器内 Continuous operation in the whole process of filtration, washing and drying; Operate under pressure or vacuum to realize solid-liquid separation. The cake is evenly distributed and the solid-liquid separation effect is good; The hydraulic pressure controls the rise and fall of the mixing system, and maximizes the slag holding space in the filtration; The mixing paddle is lifted and stirred, so that the filter cake and cleaning solution are fully mixed during cleaning, and the filter cake is fully washed; The drying time is greatly reduced and the efficiency is improved; The liquid outlet valve is controlled by many kinds, and the solid discharge system automatically discharges the material, reducing the labor intensity; It can be cleaned and sterilized online; The whole operation can be carried out under N2 protection, safe and reliable; Fully comply with GMP and FDA production requirements; The filter base plate is detachable, which is helpful for the thorough cleaning of the equipment and is suitable for the production of sterile APIs.

以在同一容器内 Continuous operation in the whole process of filtration, washing and drying; Operate under pressure or vacuum to realize solid-liquid separation. The cake is evenly distributed and the solid-liquid separation effect is good; The hydraulic pressure controls the rise and fall of the mixing system, and maximizes the slag holding space in the filtration; The mixing paddle is lifted and stirred, so that the filter cake and cleaning solution are fully mixed during cleaning, and the filter cake is fully washed; The drying time is greatly reduced and the efficiency is improved; The liquid outlet valve is controlled by many kinds, and the solid discharge system automatically discharges the material, reducing the labor intensity; It can be cleaned and sterilized online; The whole operation can be carried out under N2 protection, safe and reliable; Fully comply with GMP and FDA production requirements; The filter base plate is detachable, which is helpful for the thorough cleaning of the equipment and is suitable for the production of sterile APIs.

| 干燥器容积(L) | 500 | 750 | 1000 | 1200 | 1400 | 1600 | 2000 | 2500 | 3000 | 3500 | 4000 | 5000 |

| 过滤面积(m2) | 0.125 | 0.125 | 0.196 | 0.196 | 0.196 | 0.196 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 0.8 |

| 滤饼厚度(mm) | 500 | 500 | 600 | 650 | 650 | 700 | 700 | 800 | 800 | 1000 | 1200 | 1300 |

| 滤饼体积(m3) | 0.16 | 0.17 | 0.3 | 0.36 | 0.39 | 0.45 | 0.66 | 0.81 | 0.85 | 1.46 | 1.89 | 2.2 |

| 干燥器操作压力(Mpa) | -0.0987MPa - 0.098MPa | |||||||||||

| 夹套操作压力(Mpa) | 0MPa - 0.098Mpa | |||||||||||

| 设计温度(℃) | 100℃ | |||||||||||

| 装料量(L) | 250 | 370 | 500 | 600 | 700 | 800 | 1000 | 1250 | 1500 | 1750 | 2000 | 2500 |

| 主电机功率(kw) | 2.2 | 2.2 | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 |

| 搅拌器功率(kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 |

| 干燥器转速(转、分) | 0-5 | |||||||||||

| 搅拌器转速(转、分) | 0-200 | |||||||||||

| 主机重量(公斤) | 1782 | 2135 | 3273 | 3456 | 3683 | 3963 | 4282 | 4633 | 5487 | 7835 | 8255 | 8972 |

| 配套冷凝器面积(m2) | 7 | 7 | 10 | 12 | 14 | 16 | 20 | 25 | 30 | 35 | 40 | 50 |

封面.jpg)

封面1.png)

unite@unitefilter.com

unite@unitefilter.com No. 24 all the way,industrial park,new area,Wuxi

No. 24 all the way,industrial park,new area,Wuxi  0510-85956566 400-668-0669

0510-85956566 400-668-0669