- Product Description

- Design Parameters

The u-zc-g1 series cylinder scraper filter can automatically remove the particle impurities on the inner surface of the filter element through mechanical scraping, and can be continuously filtered online. U-zc-g1 filter is mainly designed for high viscosity filtration. It is applicable to the filtration with viscosity up to 800000 MPa. S and accuracy range of 50-1500 μ M. precise filtration can quickly scrape impurities off the surface of the filter element, thus effectively removing more impurities. It is suitable for the filtration of water and various viscous liquids.

The traditional filter is often blocked when it filters viscous materials and soft impurities, so it can only choose large filter or frequent manual cleaning, which has large investment, heavy work and serious waste of materials. The u-zc-g1 filter can easily solve such problems by advanced self-cleaning method, keep the filter element clean regularly, discharge the waste liquid containing high concentration impurities, reduce the waste of materials, and filter the water with poor water quality and sticky materials such as adhesive, resin, polymer, grease with obvious advantages and higher efficiency.

working principle:

working principle:

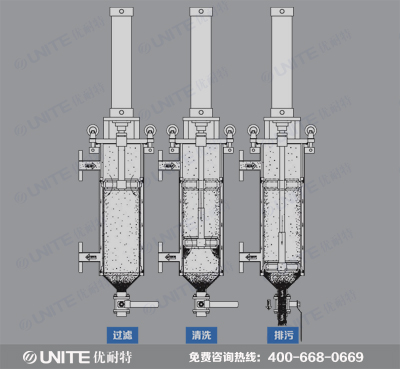

[filter status]

The liquid flows in from the inlet, the disc-shaped scraper with spring clings to the inner surface of the filter element, stops at the upper end of the filter element, the liquid passes through the scraper, flows outward from the inner surface of the filter element, the impurities are trapped on the inner surface, and the liquid flows out from the outlet; as time goes on, the impurities gradually increase, the pressure difference rises, and the filter element is cleaned according to the set pressure difference or timing.

[cleaning status]

The air cylinder drives the scraper to move up and down to clean the filter element. When the scraper moves down, the impurities are pushed to the bottom of the filter by the scraper, and the large proportion impurities precipitate to the sump. When the scraper moves upward, the residual impurities are scraped and pushed to the upper end of the filter element. The impurities are washed away by the flowing liquid. Through the scraper, they return to the inner surface of the filter element. When the scraper moves downward, they are scraped away. Each cleaning consists of several strokes. After the surface of the filter element is cleaned, the filtering capacity is restored. During cleaning, the filter is normal and the flow is not interrupted.

[blowdown status]

After several cleaning cycles, impurities accumulate to a certain amount. Open the drain valve regularly to discharge the waste liquid containing high concentration impurities. If necessary, it can also be recovered.

Internal structure:

[filter status]

The liquid flows in from the inlet, the disc-shaped scraper with spring clings to the inner surface of the filter element, stops at the upper end of the filter element, the liquid passes through the scraper, flows outward from the inner surface of the filter element, the impurities are trapped on the inner surface, and the liquid flows out from the outlet; as time goes on, the impurities gradually increase, the pressure difference rises, and the filter element is cleaned according to the set pressure difference or timing.

[cleaning status]

The air cylinder drives the scraper to move up and down to clean the filter element. When the scraper moves down, the impurities are pushed to the bottom of the filter by the scraper, and the large proportion impurities precipitate to the sump. When the scraper moves upward, the residual impurities are scraped and pushed to the upper end of the filter element. The impurities are washed away by the flowing liquid. Through the scraper, they return to the inner surface of the filter element. When the scraper moves downward, they are scraped away. Each cleaning consists of several strokes. After the surface of the filter element is cleaned, the filtering capacity is restored. During cleaning, the filter is normal and the flow is not interrupted.

[blowdown status]

After several cleaning cycles, impurities accumulate to a certain amount. Open the drain valve regularly to discharge the waste liquid containing high concentration impurities. If necessary, it can also be recovered.

Internal structure:

Filter element introduction:

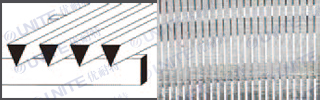

MS series filter element

Filter element introduction:

MS series filter element

MS filter element is a long slit type filter opening with isosceles trapezoid cross section, which is not easy to block impurities and can maintain a stable flow for a long time. The width of the inner surface gap is the filtering accuracy, high porosity, uniform gap, accuracy range of 50-1500 μ M. The scraper scrapes along the gap direction, which is suitable for conventional filtering requirements. The inner surface is smooth and flat, with accurate roundness and good scraping effect. Integrated precision forming, solid structure, durable. 316L material filter screen, excellent corrosion resistance. It can filter more difficult impurities, such as sludge impurities, soft caking impurities, etc.

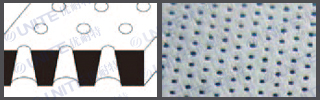

As series filter element

As filter element is made of advanced microporous processing technology, with circular filter hole and inner surface hole diameter as filtering precision and outer surface

MS filter element is a long slit type filter opening with isosceles trapezoid cross section, which is not easy to block impurities and can maintain a stable flow for a long time. The width of the inner surface gap is the filtering accuracy, high porosity, uniform gap, accuracy range of 50-1500 μ M. The scraper scrapes along the gap direction, which is suitable for conventional filtering requirements. The inner surface is smooth and flat, with accurate roundness and good scraping effect. Integrated precision forming, solid structure, durable. 316L material filter screen, excellent corrosion resistance. It can filter more difficult impurities, such as sludge impurities, soft caking impurities, etc.

As series filter element

As filter element is made of advanced microporous processing technology, with circular filter hole and inner surface hole diameter as filtering precision and outer surface

The face diameter is slightly larger, the hole channel is trumpet shaped, and the hole channel is not easy to block impurities. The precision range is 50-1000 μ M. Circular filtering hole is suitable for precise filtering, 100% impurities larger than the filtering hole diameter are removed, and it is suitable for occasions with high requirements for filtering quality. The inner surface is smooth, the roundness is accurate and the scraping effect is good. 316L material filter screen has excellent corrosion resistance, and its inner surface is specially hardened and wear-resistant, durable. It can filter more difficult impurities, such as sludge impurities, soft caking impurities, fibrous impurities, etc.

Application fields:

■ application fields: petrochemicals, fine chemicals, papermaking, food and beverage, water treatment, etc.

Suitable for liquid types: waxes, kerosene, monomers, polymers, citric acid, fermented liquid, chitosan, cosmetics, agarose (gel), silicone solution, soap, sorbitol, steroids, syrup, wet end auxiliaries, adhesives, pigments, lubricants, coatings, resins, latex, ethanol, mixed oil, cooking oil, high temperature oil, fruit juice, diesel oil, etc.

The face diameter is slightly larger, the hole channel is trumpet shaped, and the hole channel is not easy to block impurities. The precision range is 50-1000 μ M. Circular filtering hole is suitable for precise filtering, 100% impurities larger than the filtering hole diameter are removed, and it is suitable for occasions with high requirements for filtering quality. The inner surface is smooth, the roundness is accurate and the scraping effect is good. 316L material filter screen has excellent corrosion resistance, and its inner surface is specially hardened and wear-resistant, durable. It can filter more difficult impurities, such as sludge impurities, soft caking impurities, fibrous impurities, etc.

Application fields:

■ application fields: petrochemicals, fine chemicals, papermaking, food and beverage, water treatment, etc.

Suitable for liquid types: waxes, kerosene, monomers, polymers, citric acid, fermented liquid, chitosan, cosmetics, agarose (gel), silicone solution, soap, sorbitol, steroids, syrup, wet end auxiliaries, adhesives, pigments, lubricants, coatings, resins, latex, ethanol, mixed oil, cooking oil, high temperature oil, fruit juice, diesel oil, etc.

working principle:

working principle:

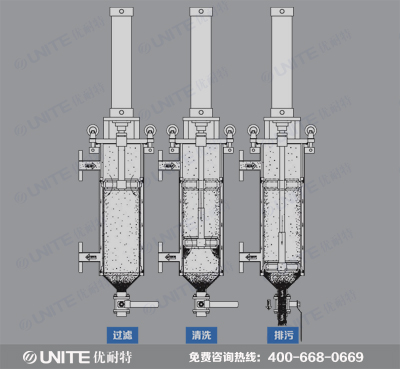

[filter status]

The liquid flows in from the inlet, the disc-shaped scraper with spring clings to the inner surface of the filter element, stops at the upper end of the filter element, the liquid passes through the scraper, flows outward from the inner surface of the filter element, the impurities are trapped on the inner surface, and the liquid flows out from the outlet; as time goes on, the impurities gradually increase, the pressure difference rises, and the filter element is cleaned according to the set pressure difference or timing.

[cleaning status]

The air cylinder drives the scraper to move up and down to clean the filter element. When the scraper moves down, the impurities are pushed to the bottom of the filter by the scraper, and the large proportion impurities precipitate to the sump. When the scraper moves upward, the residual impurities are scraped and pushed to the upper end of the filter element. The impurities are washed away by the flowing liquid. Through the scraper, they return to the inner surface of the filter element. When the scraper moves downward, they are scraped away. Each cleaning consists of several strokes. After the surface of the filter element is cleaned, the filtering capacity is restored. During cleaning, the filter is normal and the flow is not interrupted.

[blowdown status]

After several cleaning cycles, impurities accumulate to a certain amount. Open the drain valve regularly to discharge the waste liquid containing high concentration impurities. If necessary, it can also be recovered.

Internal structure:

[filter status]

The liquid flows in from the inlet, the disc-shaped scraper with spring clings to the inner surface of the filter element, stops at the upper end of the filter element, the liquid passes through the scraper, flows outward from the inner surface of the filter element, the impurities are trapped on the inner surface, and the liquid flows out from the outlet; as time goes on, the impurities gradually increase, the pressure difference rises, and the filter element is cleaned according to the set pressure difference or timing.

[cleaning status]

The air cylinder drives the scraper to move up and down to clean the filter element. When the scraper moves down, the impurities are pushed to the bottom of the filter by the scraper, and the large proportion impurities precipitate to the sump. When the scraper moves upward, the residual impurities are scraped and pushed to the upper end of the filter element. The impurities are washed away by the flowing liquid. Through the scraper, they return to the inner surface of the filter element. When the scraper moves downward, they are scraped away. Each cleaning consists of several strokes. After the surface of the filter element is cleaned, the filtering capacity is restored. During cleaning, the filter is normal and the flow is not interrupted.

[blowdown status]

After several cleaning cycles, impurities accumulate to a certain amount. Open the drain valve regularly to discharge the waste liquid containing high concentration impurities. If necessary, it can also be recovered.

Internal structure:

Filter element introduction:

MS series filter element

Filter element introduction:

MS series filter element

MS filter element is a long slit type filter opening with isosceles trapezoid cross section, which is not easy to block impurities and can maintain a stable flow for a long time. The width of the inner surface gap is the filtering accuracy, high porosity, uniform gap, accuracy range of 50-1500 μ M. The scraper scrapes along the gap direction, which is suitable for conventional filtering requirements. The inner surface is smooth and flat, with accurate roundness and good scraping effect. Integrated precision forming, solid structure, durable. 316L material filter screen, excellent corrosion resistance. It can filter more difficult impurities, such as sludge impurities, soft caking impurities, etc.

As series filter element

As filter element is made of advanced microporous processing technology, with circular filter hole and inner surface hole diameter as filtering precision and outer surface

MS filter element is a long slit type filter opening with isosceles trapezoid cross section, which is not easy to block impurities and can maintain a stable flow for a long time. The width of the inner surface gap is the filtering accuracy, high porosity, uniform gap, accuracy range of 50-1500 μ M. The scraper scrapes along the gap direction, which is suitable for conventional filtering requirements. The inner surface is smooth and flat, with accurate roundness and good scraping effect. Integrated precision forming, solid structure, durable. 316L material filter screen, excellent corrosion resistance. It can filter more difficult impurities, such as sludge impurities, soft caking impurities, etc.

As series filter element

As filter element is made of advanced microporous processing technology, with circular filter hole and inner surface hole diameter as filtering precision and outer surface

The face diameter is slightly larger, the hole channel is trumpet shaped, and the hole channel is not easy to block impurities. The precision range is 50-1000 μ M. Circular filtering hole is suitable for precise filtering, 100% impurities larger than the filtering hole diameter are removed, and it is suitable for occasions with high requirements for filtering quality. The inner surface is smooth, the roundness is accurate and the scraping effect is good. 316L material filter screen has excellent corrosion resistance, and its inner surface is specially hardened and wear-resistant, durable. It can filter more difficult impurities, such as sludge impurities, soft caking impurities, fibrous impurities, etc.

Application fields:

■ application fields: petrochemicals, fine chemicals, papermaking, food and beverage, water treatment, etc.

Suitable for liquid types: waxes, kerosene, monomers, polymers, citric acid, fermented liquid, chitosan, cosmetics, agarose (gel), silicone solution, soap, sorbitol, steroids, syrup, wet end auxiliaries, adhesives, pigments, lubricants, coatings, resins, latex, ethanol, mixed oil, cooking oil, high temperature oil, fruit juice, diesel oil, etc.

The face diameter is slightly larger, the hole channel is trumpet shaped, and the hole channel is not easy to block impurities. The precision range is 50-1000 μ M. Circular filtering hole is suitable for precise filtering, 100% impurities larger than the filtering hole diameter are removed, and it is suitable for occasions with high requirements for filtering quality. The inner surface is smooth, the roundness is accurate and the scraping effect is good. 316L material filter screen has excellent corrosion resistance, and its inner surface is specially hardened and wear-resistant, durable. It can filter more difficult impurities, such as sludge impurities, soft caking impurities, fibrous impurities, etc.

Application fields:

■ application fields: petrochemicals, fine chemicals, papermaking, food and beverage, water treatment, etc.

Suitable for liquid types: waxes, kerosene, monomers, polymers, citric acid, fermented liquid, chitosan, cosmetics, agarose (gel), silicone solution, soap, sorbitol, steroids, syrup, wet end auxiliaries, adhesives, pigments, lubricants, coatings, resins, latex, ethanol, mixed oil, cooking oil, high temperature oil, fruit juice, diesel oil, etc.

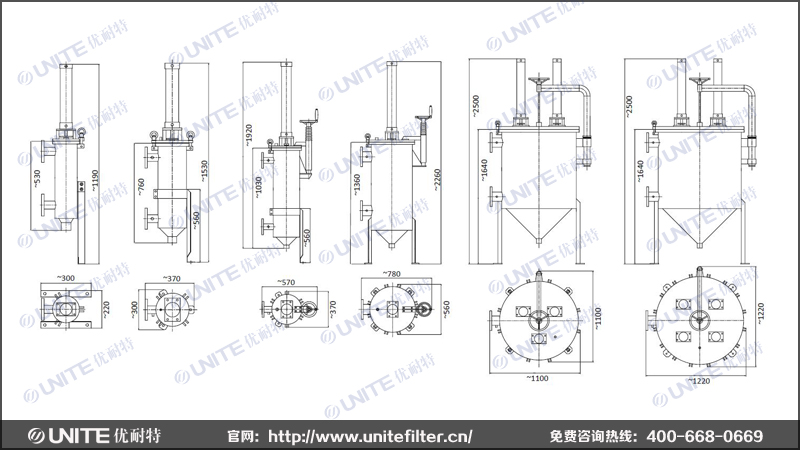

Product data sheet:

| Filter main model | U-ZC-G1-7 | U-ZC-G1-22 | U-ZC-G1-41 | U-ZC-G1-71 | U-ZC-G1-213 | U-ZC-G1-284 | ||||||

| Filtering area (M2) | 0.07 | 0.22 | 0.41 | 0.71 | 2.13 | 2.84 | ||||||

| Filter element quantity | 1 | 1 | 1 | 1 | 3 | 4 | ||||||

| Volume (L) | ~4 | ~24 | ~42 | ~175 | ~620 | ~798 | ||||||

| Size of inlet and outlet | DN25-DN50 | DN50-DN80 | DN65-DN100 | DN80-DN125 | DN98-DN150 | DN150-DN250 | ||||||

| Size of drain outlet | DN40 | |||||||||||

| Applicable liquid | Applicable to liquid water and viscous liquid (< 800000 MPa. S), impurity mass < 1000 ppm | |||||||||||

| Filtering accuracy | 50-2000μm | |||||||||||

|

Standard design pressure |

1.0MPa, higher design pressure can be customized | |||||||||||

| Design temperature | 0-200℃(取决于密封件) | |||||||||||

| Cleaning pressure difference | 50-100KPa(视液体粘度而不同) | |||||||||||

| Differential pressure instrument | Pressure transmitter / differential pressure transmitter | |||||||||||

| Import and export connection standard | 法兰,HG20592-2009(兼容ANSIB16.5);DIN11851圆螺纹活接 | |||||||||||

| Filter element series | U-M/U-A | |||||||||||

| Shell wetted material | 304/316L/CS | |||||||||||

| Piston rod material | 316L | |||||||||||

| Scraper material | PTFE polytetrafluoroethylene | |||||||||||

| Shell sealing material | NBR / EPDM / Viton / silicone rubber / FEP coated silicone rubber | |||||||||||

| Filter element sealing material | NBR/EPDM/VITON/硅橡胶/FEP包覆硅橡胶 | |||||||||||

| Sealing material of piston rod | NBR/PU聚氨酯/VITON | |||||||||||

| Drain valve | Full bore pneumatic ball valve, single or double acting, 304 / 316 | |||||||||||

| Public supply requirements | 220V AC, 0.4-0.6mpa clean and dry compressed air for control system | |||||||||||

| Custom design | Customized design jacket design, heat transfer oil or steam, liquid temperature and fluidity explosion-proof design, including instrument and control system, safe filtration of flammable and explosive liquid food level design, safety and health, easier to clean | |||||||||||

unite@unitefilter.com

unite@unitefilter.com No. 24 all the way,industrial park,new area,Wuxi

No. 24 all the way,industrial park,new area,Wuxi  0510-85956566 400-668-0669

0510-85956566 400-668-0669